| H Frame |

|

H Frames consists of rigidly welded frames of maximum three vertical and two or more horizontal elements. The frames are connected by scissor cross braces through pins with spring clips or gravity locks that are welded on frames.

By utilizing one size or a combination of varying sizes of H Frames, towers or an array can be erected to the exact height required for the job. These frames can also be erected on varying ground levels like staircases, etc.

|

|

| Using cross braces and selection of the locating pins on the frames, platform span up to 8' (2400 mm) can be achieved. This rigid sway free structure has no loose fittings and no tools are required for erection.It can be quickly and easily erected even by unskilled labour without any supervision of a structural engineer. |

| |

| H Frames Applications |

| H Frames satisfy the requirement for construction scaffolding, a versatile access system with variability of platform height and a choice of platform areas. These construction scaffolding components are already used in a wide cross section of industries, from construction and interior design to air-conditioning ducting and exhibitions. Though ideally used as access scaffolding its versatile use can also been seen in support of high slabs and bridge girders. Access stairways can also be erected on H frames. |

| |

| Mobile Tower |

| Mobile Tower are made of simple cuplock scaffolding with castor wheels at the buttom to move the Tower along with manpower & materials to convenient places as required. |

|

| |

| Scaffold Ladder |

| Scaffold Ladders are used by personnel to climb up to the required level to inspect, approve of the work carried out. These are usually made out of rectangular pipes and square pipes with rungs spaced at convenient heights for easy climbing. The hooks allow to hook on to the transoms to give stability to the ladder. |

|

X |

1500 |

2000 |

2500 |

Y |

1500/2000 |

1500/2000 |

1500/2000 |

Z |

300/350/450/500/650 |

300/350/450/500/650 |

300/350/450/500/650 |

|

|

| |

| Cantilever Bracket |

| These brackets are versatile and easy to use. They are capable of supporting more the 400kgs. easily. |

|

| |

| 'U" Head |

Height (x) |

350 |

400 |

500 |

600 |

700 |

Size solid/hollow |

ø32 |

ø36 |

ø38 |

|

|

All dimensions in mm |

|

|

| |

| |

| 2 Way 'U" Head |

Height (x) |

350 |

400 |

500 |

600 |

700 |

Size solid/hollow |

ø32 |

ø36 |

ø38 |

|

|

All dimensions in mm |

|

|

| |

| |

| Universal Jack |

Height (x) |

350 |

400 |

500 |

600 |

700 |

Size solid/hollow |

ø32 |

ø36 |

ø38 |

|

|

All dimensions in mm |

|

|

| |

| |

| Adjustable Base Jack |

Height (x) |

350 |

400 |

500 |

600 |

700 |

Size solid/hollow |

ø32 |

ø36 |

ø38 |

|

|

All dimensions in mm |

|

|

| |

| |

| Base Plate |

Height (x) |

100 |

|

|

Size solid/hollow |

ø32 |

ø36 |

ø38 |

All dimensions in mm |

|

|

| |

| |

| Adjustable Telescopic Spans |

| The most versatile and widely used system to support slab work. the span length is adjusted to the required length and both the ends are supported by means of adjusted props/verticals and the space between these spans can be filled using steel or plyforms to cast the slab. The spans are manufactured in various lengths. Maximum bending moment is 1040 kg.m, maximum total load is 2700kg and factor of safety is 2:1. |

|

| Size |

Range

(Mininum meters) |

Range

(Maximum meters) |

| ESO + ESI |

1.75 |

2.70 |

| ESO + SI |

2.35 |

3.40 |

| SO + ESI |

2.46 |

4.15 |

| SO + LI |

3.05 |

4.75 |

| LO + SI |

3.15 |

4.90 |

| LO + LI |

3.75 |

5.50 |

|

| |

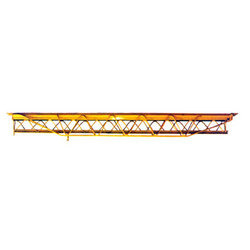

| Steel Walers |

| Are useful in holding the form work in place. These are made out of 'C channel held together by welding angles as shown in the daigram the length can be increased by using splice plates. |

|

| |

|

| Scaffolding Accessories |

|

| Scaffolding Coupler |

|

| |

|

|